Engineered & Custom Parts for Your Individual Requirements

- Custom-designed Fasteners

- Professional Prototyping

- Many Years of Experience

Manufacturing of Custom Solutions in Germany

We are specialists in custom solutions. If your project requires a special fastener that does not conform to standards and is not available on the market, GEVAG offers suitable custom parts. Thanks to our expertise, many years of experience, and excellent know-how, we deliver the required engineered part to optimally realize your project. During the development phase, we coordinate the exact requirements for the necessary component with our customers and implement them in a targeted manner. Our professional

High-performance Custom-designed Fasteners

Whether you require DIN/ISO-like fasteners that need to be adapted in detail to special requirements, or a custom solution developed specifically for you: With our expertise in the development and manufacturing of special fastening technology solutions, we purposefully realize a tailor-made, optimal solution for your project.

The starting point for the custom solution can be a drawing, a sample, or a defined connection task that you provide us for the required fastener. We are happy to accompany you already in the development phase of your project and contribute our expertise to your advantage. And: With our experience, we support you beyond the development of the fastening solution, right up to the optimal supply concept, to save resources and maximize your success.

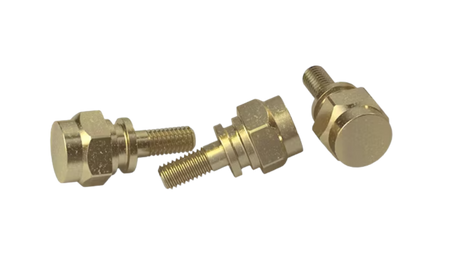

We offer custom solutions for all types of screws – also for applications involving light metals, plastics, thermosets, or as thread-forming models – as well as for bolts, nuts, set screws, washers, and locking elements. Please also feel free to inquire about desired materials or surface finishes that we can realize for you.

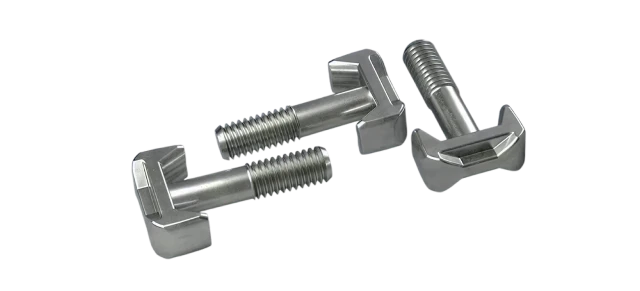

Screws for Plastic Overmolding

We offer screws with complex head geometries to position fasteners securely against rotation in battery mounting security boxes after plastic overmolding.

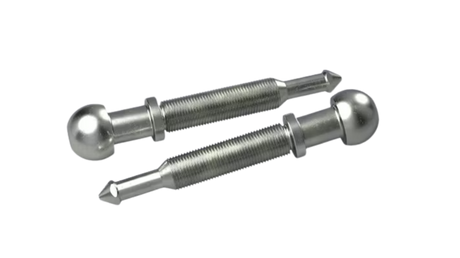

Precision Turned and Milled Parts

Whether steel, stainless steel, aluminum, copper, brass, or special materials. We offer utmost competence in small, medium, and large series production.

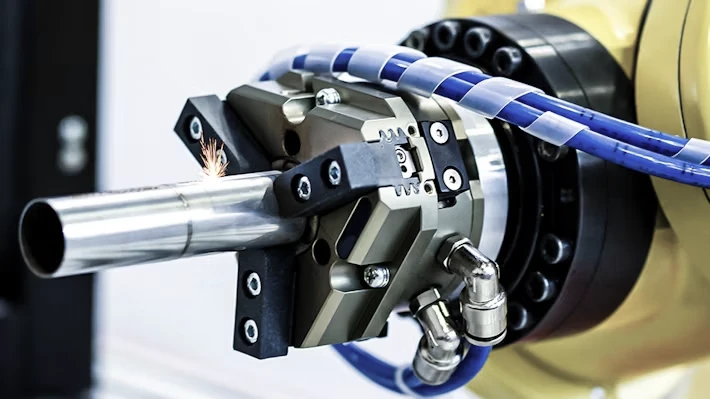

Multi-stage Forming Technology

Using multi-stage cold forming processes and split tool technology, we manufacture high-precision articles that could otherwise only be realized as turned parts. In addition to the technological advantages, we achieve maximum economic efficiency through material savings and high output volumes.

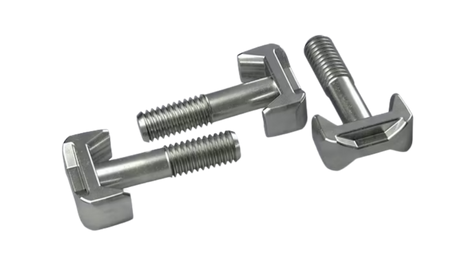

Custom Cold-Formed Parts for Power Supply Systems and Components

Our connection components guarantee a maximum level of assembly reliability for all applications in battery technology. For this purpose, we offer high-quality hammer-head screws, square-head screws, or press-in studs – for both battery-electric and conventionally powered vehicles.

Sectors and applications

Request a non-binding consultation

Contact us! Our experts look forward to assisting you.

Why GEVAG?

Since 1879, GEVAG has been dedicated to the development and manufacturing of fastening elements. Our products range from screws, bolts, nuts, set screws, and washers to securing elements, stamped and bent parts, and turned and milled parts. We supply custom-made products and standard parts according to DIN and ISO. We meet requirements in thermoplastics, steel, as well as light and non-ferrous metals with our KUNST and TAP brands. GEVAG is your powerful single-source partner.